|

USENIX 2003 Annual Technical Conference, FREENIX Track — Paper

[USENIX Annual Conference '03 Tech Program Index]

| Pp. 245-258 of the Proceedings | |

Free Software and High-Power Rocketry:

The Portland State Aerospace Society

James Perkins Andrew Greenberg

Jamey Sharp David Cassard Bart Massey

Portland State Aerospace Society

Computer Science Department

Portland State University

Portland, OR USA 97207--0751

james@psas.pdx.edu andrew@psas.pdx.edu

jamey@cs.pdx.edu dcassard@psas.pdx.edu bart@cs.pdx.edu

http://psas.pdx.edu

Abstract

The Portland State Aerospace Society (PSAS) is a small, low-budget

amateur aerospace group. PSAS is currently developing medium-sized

sub-orbital rockets with the eventual goal of inserting nanosatellites

(satellites that weigh less than 10 kg) into orbit. Because achieving

orbit requires a navigation system able to guide the rocket along an

orbital trajectory, PSAS is pioneering an open source and open

hardware avionics system that is capable of active guidance.

In this paper, we describe how free software and open hardware have

dramatically changed the capabilities of amateur aerospace groups

like PSAS. We show how we have applied existing and custom free

software to the avionics and ground support systems of a sub-orbital

sounding rocket, and discuss what further work must be done.

We conclude that the sophistication and complexity achieved by current

amateur avionics projects---which are beginning to challenge the

distinction between amateur and professional---would not be

possible without the use of free software.

1 Overview

This paper details the role of free software and open hardware in our

group, the Portland State Aerospace Society (PSAS). First we introduce

the field of rocketry, and how PSAS is making contributions to

the field. This is followed by a history of the group's rocket

development and an overview of our current project. We then cover the

details of our system, including requirements, flight software,

ground software, and the project management and

collaboration tools. Finally, we discuss our future work, and draw

conclusions about the applicability of free software to projects

like ours.

2 Introduction to Rocketry

Rocketry has a rich history of significant contributions made by amateur

groups. Indeed, most national space programs can trace their roots back

to small, active groups of amateurs working on rocketry during the early

part of the 20th century [Win83].

Amateur rocket motor classifications are categorized by their total

impulse, which is total force multiplied by burn time. ``A'' motors have

up to 2.5 Newton-seconds (Ns) of total impulse, and each successive

letter of the alphabet doubles the impulse range of the previous

letter [Tri].

Today, rocketry includes a wide spectrum of participants and can

generally be divided into four categories.

Model rocketry involves the smallest and most common types of

rockets, with motors made of pressed black powder that are smaller than

320 Ns (``H''), and bodies built out of balsa wood and cardboard or

phenolic (resin) tubes. Most model rockets weigh less than a kilogram

and are recovered with a small parachute or streamer.

Since model rockets generally stay below 460 m (1,500 ft), they avoid

most government regulation in the US.

Hobby rocketry begins from the upper limits of model

rocketry. Motors delivering up to about 10,240 Ns (``M'')

of thrust are common. Motors are typically made of

composite fuel (ammonium perchlorate in a HTPB plastic

binder), and are sometimes clustered or staged to achieve

greater power. Some high-powered hobby rockets can reach

more than 6 km (20,000 ft), so launches in the US

are government regulated and require launch waivers. Most

hobby rockets use commercially available, single board

avionics systems that sense the best time to eject

parachutes [alt], although some

custom-built avionics packages have been much more

sophisticated.

Amateur rocketry usually implies a certain level of innovation

and customization, such as custom motors, custom avionics and metal airframes.

This innovation may be inspired by a lack of suitable commercial

solutions or a desire to ``do it yourself''. The current altitude record

for an amateur group is 85 km (280,000 ft) with a 327,680 Ns (``R'')

motor [rrs].

Professional rocketry is the most familiar category. It

includes organizations such as NASA and the European Space Agency (ESA),

along with their private contractors such as Lockheed Martin, Boeing,

and Orbital Sciences.

Over time, the line between amateur and professional rocketry has

blurred. Some industry observers discriminate by financial gains, technical

expertise, or sheer altitude achieved, but there is no common standard.

Indeed, as technologies such as computational power and integrated

sensors become cheaper and more available, the capabilities of amateur

groups have begun to catch up to some professional projects.

3 The Portland State Aerospace Society

The Portland State Aerospace Society (PSAS) was founded in 1997 by two

students at Portland State University (PSU) in Portland, Oregon to

provide an aerospace-based, systems-level educational design project.

PSAS has launched one hobby and two high-powered amateur rockets.

The group has grown to include more than three dozen people, including

high school, undergraduate and

graduate students, as well as engineers from local industry. Current PSAS

projects are focused on taking small, manageable steps towards the the

distant vision of inserting nanosatellites (satellites that weigh

less than 10 kg) into orbit.

Is it possible for amateur rocketry groups to achieve orbit? None have, to date.

In most countries, the regulatory hurdles are at least as much of a challenge for an

amateur group as the substantial technological and financial issues.

The US Commercial Space Launch Act of

1984 requires any rocket with over 890,000 Ns (``S'') of impulse lasting

for 15 seconds or more to meet stringent safety requirements set by the

FAA, NASA, and Commercial Space Transportation Board

(CSTB) [csl, sls].

These requirements include an extensive safety analysis, which can take

years and cost hundreds of thousands of dollars.

Furthermore, vehicles which actually achieve orbit must comply with

international ``space law'' as laid out in various international

agreements [un].

While fulfilling the goal of achieving

orbit may be beyond the ability of our

small group, the enabling technologies needed to get there by an amateur

group are now readily obtainable: inexpensive computational power, sophisticated

sensors, high-power actuators, and the availability of robust, open

source software for engineering and logistical support.

3.1 Toward Amateur Active Guidance

To achieve orbit at minimum cost, a rocket must follow an ``orbital

trajectory'' that minimizes both the aerodynamic drag in the lower

atmosphere and the time to get to orbit [Wer92].

To follow such a trajectory, the rocket must be able to measure

its current trajectory, compare against the planned trajectory, and

actively correct for errors. This ability to follow a trajectory is

called ``active guidance'', and the authors know of no amateur

group that has yet achieved this. To bridge this gap

in amateur rocketry technology, PSAS has chosen to work on open

source and open hardware high-powered amateur rockets that are capable

of active guidance.

There are many meanings of active guidance. Here we use active guidance

in the classic rocket sense: a guidance computer on-board the rocket measures the

rocket's current position, heading and course. The guidance

computer

then activates a

steering mechanism in order to guide the rocket along a predetermined

path.

To determine the rocket's position, attitude (orientation) and

trajectory (flight path), a rocket's flight computer uses data from

one or more sensors:

-

GPS receivers provide absolute position at a slow (~1 Hz) rate.

- Inertial Measurement Units (IMUs) provide relative linear and

rotational acceleration, velocity and position using accelerometers and

gyroscopes at a faster rate (~1 kHz).

- Magnetometers provide attitude (orientation) by comparing the

local magnetic field to a 3D map of the Earth's magnetic field.

- Pressure sensors allow altitude to be computed from atmospheric

pressure models.

- Optical sensors, such as star and horizon trackers, may be used to

compute attitude.

Each of these sensors have different signal and noise

characteristics.

Kalman filtering [CC99] is a signal processing algorithm

for combining noisy sensor data that provides guarantees on

the optimality of its estimate. This estimate can then

be used as an approximation of the rocket's true position, attitude

and trajectory.

To steer the rocket, some mechanism must apply a force to the rocket

during flight. Steering mechanisms vary widely:

-

Small fins are common, but are ineffective above about 25 km

(82,000 ft).

- Reaction Control Systems use small rocket motors to adjust the

heading of the rocket, but are usually large, heavy systems

that are

ineffective in the lower atmosphere.

- Thrust Vector Control changes the angle of the main motor's

thrust, for example by gimballing the main motor nozzle, by independently

throttling multiple clustered motors, by putting small movable vanes in the

path of the exhaust, or by injecting extra oxidizer into the

edge of a fuel-rich

exhaust stream [SB00].

To ``close the loop'', estimates of position, attitude and

trajectory are used to calculate steering commands. The most difficult

part of active guidance may be getting the signal processing in the

control loop correct. Many famous rocket failures, such as the first

launch of Ariane 5, were due to simple errors in design

or implementation of the navigation system

algorithms [ins].

3.2 Related Work

Many amateur groups exist today, but none that the authors know of

are currently working on active guidance. Guided amateur designs do

exist, but all either track the sun or are used to simply

stabilize the rocket in flight. None can actually be used to follow

a planned trajectory. An excellent example of a guided, but not actively

guided, rocket is the MARS Rocket Society's gyroscope-controlled

gimballed-nozzle rocket [mar].

3.3 Launch Vehicles

Because we strongly emphasize safety, reliability and new functionality

for every launch, PSAS has launched only four times over its six year

history. In a field with failure rates as high as 30% at some events,

we have not yet lost a vehicle. Further, each new launch has demonstrated

new airframe or avionics functionality which justified the time and

expense of performing a launch.

Table 1: Comparison of PSAS Launch Vehicles

| Name |

Size |

Dia. |

Weight |

Ns |

Altitude |

Cost |

Design |

CPU |

OS |

|

| LV0 |

1.8 m |

10.0 cm |

5.4 kg |

J |

0.3 km |

$500 |

4 mo. |

PIC16C |

Interrupt-driven |

| LV1 |

3.4 m |

11.0 cm |

19.5 kg |

M |

3.6 km |

$2000 |

18 mo. |

PIC17C |

Interrupt framework |

| LV2 |

4.0 m |

13.6 cm |

46.0 kg |

P |

23.0 km |

$10000 |

>21 mo. |

5x86 |

Linux / RTLinux |

3.3.1 Launch Vehicle No. 0

The first PSAS project began with four volunteers and a simple hobby

rocket dubbed ``Launch Vehicle No. 0'' (LV0). The team modified a

commercial kit of cardboard tubes and balsa wood with fiberglass and

epoxy resin and added a simple avionics system.

While the airframe took only a weekend to complete, the avionics system

took two people a few months of building and testing. The avionics

system had just a few components: a 1 MHz 8 bit RISC microcontroller;

a micro-electro-mechanical (MEMs) accelerometer;

a 426 MHz 1 W amateur television (ATV) transmitter;

a monochrome video camera; and a commercial logging altimeter.

The interrupt-driven microcontroller firmware was written in assembly

language. Accelerometer samples were downlinked using the ATV audio channel

at 300 bps. Telemetry data was then logged on a 386 DOS laptop.

LV0 was launched on June 7, 1998 (Table 1).

Not surprisingly, things went wrong. The airframe was all

but unstable and a short circuit in the wiring harness erased system

memory. However, the received images and data proved the

soundness of the overall system concept.

3.3.2 Launch Vehicle No. 1

LV0's success attracted more volunteers: about a dozen people designed

and built the next generation rocket, Launch Vehicle No. 1 (LV1). The

airframe was made of carbon fiber over a PVC and aluminum core, and was

built by one person over 3 months, with little engineering analysis.

The LV1 avionics system was arguably the most advanced

amateur rocket avionics package in the world in 1999. Its subsystems included:

-

A custom flight computer board with an 8 bit 33 MHz RISC

microcontroller, 1 MB of non-volatile SRAM for data logging,

pyrotechnic ignition circuitry, and interface circuitry to

other subsystems including temperature and pressure sensors.

- An inertial measurement unit (IMU): X, Y, and Z axis linear

accelerometers and yaw, pitch, and roll rate gyroscopes. These sensors

produced a ``six degree of freedom'' measurement which was

numerically integrated to calculate the rocket's 3D position and velocity.

- A commercial 12-channel GPS receiver.

- A color video camera and microphone that transmitted over a 426 MHz ATV

transmitter.

- A 913 MHz 1 W transmitter that sent 19.2 kbps telemetry data encoded by

the flight computer.

- A 146.43 MHz (2 m) amateur radio receiver with a DTMF decoder.

Decoded tones were sent to an independent microcontroller

that could fire the

recovery system or send commands to the flight computer

in an emergency.

The flight computer's assembly-language, interrupt-driven executive

sampled all sensors, logged data, and transmitted low-pass filtered

telemetry. The firmware also used the GPS, IMU and pressure sensors to

determine the rocket's altitude and thus when to deploy the recovery

system.

LV1 required extensive ground support due to its size and complexity. A

surplus pneumatic lifter was modified into a launch tower with a 6 m

(20 ft) launch rail. Launch control software automatically performed the

countdown and launched the rocket via a 903 MHz wireless link

to a small microcontroller-run relay board.

Another Linux-based ground computer captured, logged and displayed

live telemetry data with a custom GTK-based application. This

helped the range safety officer decide if the flight was proceeding as

planned: if not, the emergency radio could be used to deploy the

recovery system (parachutes) even if the flight computer failed.

LV1 was launched on April 11, 1999 and again (as LV1b) on October 7,

2000 (Table 1). Half of the $2,000 development cost

came from an IEEE/AT&T ``Student Enterprise'' grant.

LV1's complexity led the dozen-plus volunteers to divide into airframe,

avionics and logistics teams. Each team had their own mailing list, web

page and FTP folders. However, formal design methods were mostly

ignored and the web site was updated infrequently. Designs were

implemented without review, which caused schedule slips and and two

``scrubbed'' launches.

3.3.3 Launch Vehicle No. 2

The next generation launch vehicle needed the flexibility, modularity

and extensibility that LV1 lacked. A few of the lessons learned include:

-

Real-time Operating Systems (RTOS's) hand-built in assembly language

are not a good idea for a complex, multi-volunteer effort. An

off-the-shelf RTOS with better networking and free, easily learned

development tools is much more appropriate.

- The navigation software needs serious computational power:

a CPU with hardware floating point support is highly desirable.

- Subsystems in the avionics system must be easily added, removed

or swapped.

- The airframe itself must be flexible and expandable to

handle unforeseen requirements.

The design of LV2 took more than a year of careful coordination between

the avionics and airframe teams. The

design process was much more formal than had

previously been tried. A white paper was written on the various design options

for the avionics system. The airframe team used finite-element analysis

to predict the performance of different airframe structures. To fund

the project, PSAS applied for and won the 2000 Oregon Space Grant,

a $10,000 NASA-sponsored small grant program.

The LV2 airframe uses a flexible and modular design to facilitate swapping

out entire subsystems such as the avionics, recovery or propulsion

(motor) unit. We have also separated the

avionics system from the payload module, enabling LV2 to fly other

academic or amateur rocketry payloads. The resulting airframe

is made of cylindrical aluminum modules covered by a fiberglass aeroshell.

Simulations predict a maximum altitude of 23 km (75,000 ft)

(Table 1).

Based on a computational complexity analysis of the navigation software,

we decided to use a flight computer with a floating point unit (FPU),

better support for multitasking, and a modern development toolchain.

However, a single-processor avionics system was unappealing because of

the high-rate, I/O-intensive tasks many of the sensors

required:

controlling a high speed analog-to-digital converter and

running a closed loop motor controller, for example.

A multi-node common bus solves many of these problems by enabling a larger,

more powerful central flight computer to communicate with many smaller

microcontrollers. This allows a ``smart

sensor'' and ``smart actuator'' approach that frees up the central

processor to perform higher-level calculations and

supervisory tasks.

We chose the Controller Area Network (CAN) bus as our intra-rocket

multi-node bus. The CAN bus is an automotive bus developed

by Robert Bosch, GmbH which is quickly gaining acceptance in both the industrial

and aerospace markets. CAN is a multi-master, losslessly-arbitrated

serial bus that can be run up to 1 Mbps. The CAN bus includes

packet-level checksums and tolerance of node

errors (including logic that forces a node off of the bus if it

is causing errors). Perhaps the most interesting aspect of CAN is its

message-based identification of packets: instead of node addresses, the

CAN bus identifies and prioritizes the messages based on an 11 bit

identifier. Each message, such as GPS location, or IMU inertial data,

is broadcast on the bus with a unique message ID [can].

For the central flight computer we have selected the PC104

form-factor. This allows us to use standard off-the-shelf

parts instead of taking the time and effort to make our

own. The flight computer consists of:

-

A Jumptec MOPS520 PC104+ board, a 133 MHz 5x86 processor (the AMD SC520)

with 64 MB of SDRAM, typical PC ports, and a CAN interface.

- A carrier board for a 128 MB CompactFlash hard disk.

- A PCMCIA carrier board for a Lucent Orinoco 802.11b card.

Considerable

difficulty was encountered in developing the wireless telemetry system for

LV1. We thus wanted a commercially available long-range

high-speed bi-directional wireless telemetry system for LV2:

such a system could be used for telemetry

as well as by the rocket, launch tower and ground

computers. After some research, we gravitated toward the Amateur Radio

Relay League (ARRL) 802.11b standard. ARRL

802.11b is the IEEE 802.11b 2.4 GHz spread spectrum standard, but

operated under the FCC amateur radio regulations (FCC Part 97) instead of

the low-power, unlicensed regulations of the 2.4 GHz ISM band (FCC Part

15). Running under ARRL 802.11b allows us to use up to 100 W of radiated

power. Our current system uses a standard PC-Card (Lucent Orinoco), a

1 W bidirectional power amplifier, and high gain (+12 dB) helical ground

antennas [arr].

The smaller sensor/actuator CAN nodes use the Microchip PIC18F458, an

8 bit, 40 MHz RISC flash-memory microcontroller with a built-in CAN protocol

unit. There are currently five CAN nodes:

-

The LV1 IMU.

- A SigTech Navigation MG5001 OEM GPS receiver.

- A power interface node to control system power and track battery

charge.

- A recovery node---a battery-backed up CAN node with high voltage

pyrotechnic firing circuitry. Like LV1, it has a 2 m amateur radio

receiver which decodes DTMF tone sequences sent as emergency commands.

- An ATV node, consisting of a color video camera, ATV transmitter, power

amplifier and an overlay board that displays textual vehicle

status information along

with NTSC flight video.

The CAN nodes have proven to be useful general-purpose

building blocks: new nodes are frequently

prototyped atop a generic ``misc CAN node'' design.

4 Software Overview

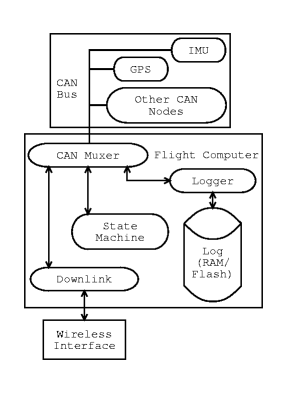

Figure 1: LV2 System Software

The software system is divided into three major areas:

-

Flight Software

-

Flight Computer Software flies in the rocket, and runs on a

single-board computer running Debian GNU/Linux

(Section 5.1).

- Avionics Firmware flies in the rocket, and runs on multiple

independent microcontroller nodes (Sections 5.2--5.3).

- Ground Software

-

Launch Control Software is used by the

flight control officer

to sequence the rocket launch. Launch Tower Software

manages launch tower electronics (Section 6.1).

- Telemetry Display Software is used by the flight

control officer and

spectators to view the rocket's status.

(Section 6.2).

- Uplink Software is operated by the range safety officer at

launch control and sends emergency commands through the 2 m uplink

(Section 6.3).

- Collaboration Software runs on the (Portland State

University) hosted PSAS server.

The PSAS server is the locus for a variety of services

including mailing lists, collaborative web

pages and CVS repositories (Section 7).

4.1 Functional Requirements

There are a number of mandatory requirements for a successful

rocket launch. In order of priority:

-

Safety. The risk of death, injury, and property

damage must be minimized

- Reliable Recovery. The airframe

must be safely recovered. The principal software constraint

is to deploy the recovery

parachute only at apogee, when vertical airspeed is at a minimum.

- Flight Data Recovery. The purpose of every flight is to

collect new data: data recovery is thus essential.

- Telemetry Downlink. Real time sensor data must be

easily monitored by the launch controller to decide whether or not to

override the flight computer via the emergency uplink.

- Radio Dropout Tolerance. Radio links are notoriously

unreliable. The software must be able to tolerate link failures.

- Recovery Assistance. Position information must be

available to the recovery teams tracking the rocket after the parachutes

have opened. High winds or malfunction can carry the rocket

kilometers away during ascent or

descent.

- Power Management. Intelligent power management is

crucial to reliable performance. Power use also constrains

peak altitude. Lithium batteries store energy at a density of

~300 WHr/kg. Thus,

during a

standard flight profile each watt used on the rocket adds 30 g

(1.1 oz) of battery weight. Simulations predict that the altitude-

to-weight ratio is -335 m/kg. Thus every watt used on the rocket

means a reduction of 10 m (33 ft) of altitude.

4.2 Logistical Requirements

The volunteer nature of our group imposes some special

project management requirements:

-

Minimize Coordination Overhead. In our

project, collaboration is entirely ad-hoc. Project synchronization and access

control mechanisms must reflect this.

- Minimize Training. Well-known development methods

are necessary to enable immediate contributions

by our new volunteers.

- Limit Costs. Funding is scarce: we must take advantage

of any available cost reductions.

4.3 Choosing a Common Platform

Our requirements for a low-cost, reliable and flexible platform

discourage the use of non-free, proprietary and unfixable software

and suggest using well-documented, open-standards-based

free software. GNU/Linux not only runs on the limited

hardware we have available, but also enables the use of thousands of

free software applications available for UNIX environments.

We have standardized on the Debian GNU/Linux distribution for all of our

development, collaboration and rocket systems in order

to reduce the amount of time spent maintaining and installing

software [deb].

Thanks to Debian's Advanced Package Tool (apt),

our systems generally require little maintenance effort

while remaining relatively secure.

This enables us to focus on our development efforts

instead of struggling with platform and tool configuration. It also

reduces the time necessary to configure development environments for our

new volunteers.

4.4 From Soft to Hard Real-time

The term ``real-time'' refers to applications that require guaranteed

bounds on the time between the occurrence of an event and the software's

response. Soft real-time requirements allow for occasional missed

deadlines under high load, but hard real-time applications must meet all

deadlines under all conditions [Lab99].

Linux is designed to optimize throughput, not to guarantee

hard real-time

response. Processing may be delayed by mutexes,

interrupt locks, high interrupt load, paging, and other causes. The

scheduling latency of a Linux task may be improved using the

sched_setscheduler() system call to identify it as a ``real-time''

task. Other tricks include using mlock() or mlockall() to avoid paging delays, and enabling

full kernel preemption using various kernel patches [Gal95].

While these approaches improve mean response time, the

system

delays are still unbounded.

One approach to regions of code requiring hard

real-time response is to move them below the user API into or below the

kernel,

where the code paths and potential interruptions to them can be fully

understood. For example, interrupt handlers might be used to schedule

Linux kernel threads, limiting code analysis to the interrupt handler

path.

For full control over response time, the entire flight computer

application could be run on a hard real-time operating

system. There are several light-weight commercial

offerings, such as Wind River's VxWorks operating

system, the QNX Microkernel and Jean Labrosse's

MicroC/OS-II. However, commercial RTOS's

generally require specialized programming knowledge, often support

a narrower array of devices than free software, and can

be expensive.

Fortunately, the best of both worlds may be found in real-time operating

systems that run the entire Linux kernel and all user processes in the

lowest-priority thread. One such offering is FSMLabs

Inc.'s RTLinux [fsm].

The hard real-time elements of our software can be implemented using the

real-time kernel primitives: everything else runs as Linux user

processes.

The PSAS flight computer application has a variety of requirements.

Some components have no real-time requirement, while others have soft or hard

real-time requirements. For the next launch, our application's real-time

requirements are soft: launch and apogee must be detected and handled

within a second, and data must be logged and transmitted to the

ground as soon as possible. However, the introduction of navigation

algorithms on future launches will require us to move to hard real-time,

and we plan to begin using RTLinux with our Fall 2003 launch.

5 Flight Software

Table 2: Processors used in the LV2 Avionics System

| System Name |

Arch. |

Bits |

Speed |

RAM |

Flash |

MMU? |

OS |

|

| Flight Computer |

AMD 5x86 |

32 |

133 MHz |

64,000 KB |

128,000 KB |

Y |

Linux |

| GPS Receiver |

ARM7TDMI |

32 |

40 MHz |

128 KB |

1,000 KB |

N |

eCos |

| CAN Nodes |

PIC18 |

8 |

40 MHz |

2 KB |

32 KB |

N |

PicCore |

The LV2 flight system uses three significantly different

kinds of processors (Table 2). This

necessitates three significantly different software

architectures: processes running in a 32 bit pre-emptive

multitasking RTOS; threads running in a light-weight

POSIX-compatible RTOS; and tasks running in a custom

interrupt-driven framework. In this section we review these

software architectures. Note that we distinguish firmware

from software: firmware consists of small, hardware-oriented

programs stored in nonvolatile memory and considered read-only by

the local processor.

5.1 Flight Computer Software

A key element of the application software running on the

5x86-based flight computer (see

Section 3.3.3) is its message-passing

architecture. This software is currently written in C, and

runs in a Debian GNU/Linux environment with a Linux 2.4

kernel. Messages are passed across the wireless link,

across the CAN bus and to the nonvolatile data log

(Figure 1).

Every component of the PSAS avionics system has different response speed and latency

characteristics. In order to avoid holding up the whole application,

each device is monitored and controlled by one or more

asynchronous execution tasks. Coordination of these tasks is

accomplished by passing messages between them, initially by using a

message server task.

We have been through three flight computer software designs

with

different message-handling schemes: ``Muxer'',

``Renegade'' and ``FCFIFO''.

After introducing these designs, we will discuss some other

flight-computer software elements of interest: the CAN Bus driver and

our network configuration.

Figure 2: Muxer Flight Computer Software Design

The first design was implemented in C using POSIX threads, TCP/IP

sockets, and device I/O processes. The processes passed messages by

connecting to a server process called Muxer, which broadcasted

each message received to every other task.

Muxer's server thread began by

initializing a shared buffer. It then

listened for TCP/IP connections. The central data structure was a

variable-sized shared queue of messages. When a client connection was

accepted, the server thread spawned client queue reader

and writer threads. The new client's queue reader thread slept, waiting for new

messages to arrive in the queue. The client's queue writer waited for an

incoming message and enqueued it. Queue access was serialized by a

mutex, and semaphores were used to wake sleeping queue

readers when

new messages were waiting for delivery. The last client to read a

message from the queue deallocated that queue element.

The Muxer design included a client library to ease creating a TCP/IP

connection to the Muxer service. Clients were mostly other Linux

processes on-board the flight computer or (via the wireless link) on the

ground (Figure 2).

A shell script first started the Muxer server process, then each of

the client processes.

The client processes would open and initialize their I/O device.

They would then use the Muxer client library to open a connection to the Muxer

server thread.

There were some difficulties with this design:

-

Excessive wake-ups. The star message topology with N clients

resulted in each new message waking up N threads, which wrote N messages

to the network stack, which woke up N processes to read the data.

- Message synchronization. Messages were of variable size, making

mid-reception synchronization to a message stream a challenge.

- Debugging. Debugging POSIX threads was

difficult. Threads would sometimes damage the environment

of their neighbors.

- Opacity. The queue structure, its mutex and use was not easily understood

by the team.

- Wrong protocol. TCP/IP was a poor choice for

wireless communications, incurring multi-megabyte

queuing and retries in the network layer. Ultimately a downlink process

was added to bridge the messages into a UDP protocol for the wireless downlink.

A CAN bus reader was implemented and Muxer was demonstrated to

work. Nonetheless, when changes were introduced that broke

Muxer,

no one was able

to find the time to sort out why. Team members eventually realized

that solving the flight computer design problem by starting from the

message handling structure and then moving out from there was not

working.

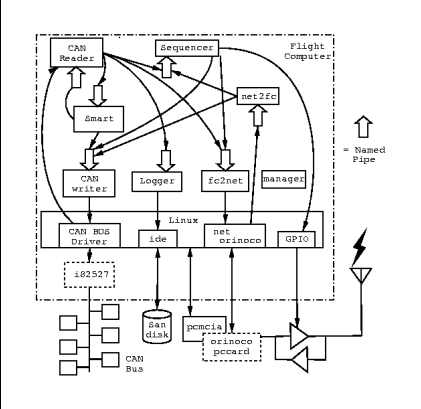

Figure 3: Renegade Flight Computer Software

Design

One team member began working on an independent effort, and titled it

the ``Renegade'' design. Renegade continued the theme of a central

Muxer task dispatching each message to all asynchronous I/O-handling

clients. However, the architecture

was implemented as a UNIX process with UNIX pipes to

child I/O processes (Figure 3).

The top-down, application-oriented and simplified design was an

improvement. Most importantly, needed rocket functionality was quickly

completed:

-

CAN bus messages were read and distributed

successfully to all I/O devices.

- Intertask communication became independent of networking.

- Wireless dropouts were handled efficiently rather than

causing backups.

- Fixed-sized messages eliminated synchronization issues.

- Debugging with GDB and UNIX signals was trivial.

- The Linux kernel design could be relied on for optimized

intertask performance.

Renegade did have shortcomings.

-

The lack

of message filtering and

the broadcast architecture still

led to excessive wake-ups.

- The inherited pipe structure made it difficult to restart I/O

processes from the shell.

- UNIX pipes were difficult to inject data into for testing

and debugging.

- No throughput tests were ever attempted.

After some consideration of Renegade's shortcomings, we once

again decided to redesign

the flight computer software to correct them.

Figure 4: FCFIFO Flight Computer Software

Design

The third and completed design is called FCFIFO. It combines the

independent processes from the Muxer design with the conventional UNIX

interprocess communications of Renegade. In addition, it eliminates the

central multiplexer (Figure 4).

On startup, each process

opens a uniquely named pipe to read messages from, then opens

the named pipes of any processes it needs to communicate with. By

eliminating the central multiplexer, task switch and copying

overhead are minimized.

A simple Linux user-mode process-oriented application will satisfy the

June 2003 soft real-time requirements. While named pipes do not

guarantee a response time, they do aid in maximizing throughput.

They also allow processes to run asynchronously, because

they can

buffer a

few messages if the reading process falls behind. As components

transition to RTLinux hard real-time tasks, this architecture will be

ideal: named pipes are the preferred means of communication between

Linux and RTLinux tasks.

Where it is advantageous for activities to occur independently, the

application implements these via separate processes.

-

Logger takes messages on its named pipe and stores them

in the nonvolatile log file.

- CAN Reader opens the CAN bus device and blocks until it

reads a message either from the CAN bus or from its named pipe. It

passes messages to the Logger and networking for storage, sensor

information to Smart, and a few other events to Sequencer.

- CAN Writer opens the CAN bus device for writing and waits

for incoming CAN messages on its named pipe. It then sends those

messages out onto the CAN bus.

- Fc2Net waits on its named pipe for a message, then

broadcasts the message to the wireless network using our UDP application

protocol.

- Net2Fc initializes a UDP server port, then waits for a

message. If a command comes from the ground via the wireless

network,

Net2FC

passes the command on to other relevant processes.

- Smart evaluates raw sensor data and converts it into a

more useful form. (We discovered that this is a difficult component to

name. After much thought, we decided it is the ``Smart Module Assembling

Real-time Tasks''.) For example, GPS and IMU data are

processed to obtain

position, velocity, and acceleration information. Smart also detects events such as

rocket launch, apogee, and touchdown.

- Sequencer decides when the system should transition

from one rocket flight state to another, and generates the commands

needed to set up the CAN nodes for the new state.

- Manager is analogous to the UNIX init process. It starts

the whole set of named pipe children, restarts children that die

unexpectedly, and manages a graceful application shutdown.

5.1.4 Linux CAN Bus Driver

CAN communication is performed through a GNU GPL

82527 CAN chip driver for Linux, written by Arnaud

Westenberg and adapted

to our the flight computer's 82527 interface [lcb].

The driver allows applications to communicate with the CAN bus through

the /dev/can0 device node.

5.1.5 Network Configuration

During development, the flight computer communicates with development

machines using its built-in Ethernet or local IEEE 802.11b wireless. In flight

configuration it uses the ARRL 802.11b hardware described in

Section 3.3.3. Standard Linux PCMCIA and Orinoco drivers

configure and integrate the network hardware.

However, a simple custom

driver is needed to switch the system between IEEE and ARRL 802.11b

modes: the 2.4 GHz bidirectional power amplifier can be turned on and

off via two general purpose I/O pins on the flight computer.

The wireless network card is configured to use channel zero (2.400 -

2.450 GHz, which is within the amateur 13 cm band), IBSS ad-hoc

networking mode, a fixed IP address from a private network address

range, and the maximum power output available from the card.

Enabling IBSS ad-hoc networking prevents the card from participating

in auto-configuration via a management device such as a wireless

access point. The telemetry viewing computers at launch

control are the only other device similarly configured, to limit

performance-robbing traffic collisions.

All network transmissions between the rocket and ground control use UDP

broadcast packets. This provides a low-overhead transmission path with

no packet retries. TCP was briefly considered for rocket communications,

but TCP requires a reasonably error-free communications medium. Given

the extreme 23 km distance of the rocket , antenna geometry effects, attenuation

due to the motor's exhaust plume, and tracking error of the ground

antennas, it cannot be assumed that the wireless link can support

TCP communications.

The telemetry and control protocol is symmetric, time-stamped, and is

logged on each end. This allows us to measure communications loss through

post-flight data analysis. Periodic general status messages from

the rocket allow the ground software to resynchronize key parameters

rapidly even when

communication is intermittent. A data payload checksum helps validate the

quality of the received data, although invalid data frames are also

logged to aid in link quality analysis.

5.2 CAN Node Firmware: ARM7TDMI

The Global Position System (GPS) receivers on-board LV2 are commercially

available boards that use the Zarlink GP4020 GPS correlator

chip [gpsb], a custom ASIC with a 12-channel correlator and an

ARM7TDMI microcontroller core. The receivers come with closed-source

proprietary firmware which runs the correlators, processes the satellite

data, and transmits position and velocity information over a standard

asynchronous serial bus.

Unfortunately, the navigation algorithms in commercially available GPS

receivers fail to cope with the high dynamics of LV2 and will lose

satellite lock when the vehicle exceeds 515 m/s, 18 km in altitude,

or 8 g's of acceleration. Because LV2 will exceed these limits and a

locked GPS receiver is a critical part of our navigation system, we have

started a separate project: developing free firmware for GPS receivers which

use the GP4020 chip. Dubbed GPL-GPS [gpsa], the firmware is

based on Clifford Kelley's ``OpenSource GPS''

project [kel] and will allow the receivers to stay locked

during highly dynamic flights. The open firmware will allow us to

implement our own sophisticated processing techniques,

including integrating the GPS and IMU into a GPS-aided inertial

navigation system [FB99]. The firmware may also allow us to:

-

Implement local differential GPS corrections via a similar GPS

receiver on the ground in a known, static position. Enabling a local

differential base station can yield positioning accuracies

in the 1 m range.

- Use multiple GPS

receivers to determine attitude (orientation) by comparing the

position of their antennas.

- Keep GPS lock on the satellites by integrating data from the inertial

measurement unit to aid the correlator tracking loops.

We chose to use an existing RTOS in order to speed up firmware

development, and because a multi-threading abstraction will simplify

the GPS firmware design. GPL-GPS requires an RTOS with extremely low

latency, POSIX compliance to facilitate porting, a reasonable free

or open-source license, ability to run in 1 MB of flash memory and 128 KB of

RAM, and a reasonable effort level (estimated as a time

multiplier) for us to implement with our

hardware.

Based on our research (Table 3), we selected Red Hat's eCos

(embedded Configurable Operating System) [Mas03] as the best fit to our

criteria. We are currently working on the alpha release of the GPL-GPS

project, which includes a port of eCos and Kelley's OpenSource GPS to

the GP4020. We hope to have initial results by September 2003.

Table 3: Embedded Operating Systems Comparison

| Name |

RT |

POSIX |

Free |

Small |

Effort |

|

| RTLinux |

Y |

Y |

Y |

N |

1x |

| µcLinux |

N |

Y |

Y |

N |

2x |

| MicroC/OS-II |

Y |

N |

N |

Y |

4x |

| µITRON |

Y |

N |

Y |

Y |

4x |

| eCos |

Y |

Y |

Y |

Y |

4x |

| Custom |

Y |

N |

Y |

Y |

10x |

5.3 CAN node Firmware: PIC18

The Microchip PIC18F458 8 bit RISC microcontrollers [pic] used on the CAN nodes

(see Section 3.3.3) have 1.5 KB of RAM, 32 KB of

flash memory. and a long list of peripherals. The latter

include an 8-channel 10 bit analog to digital converter,

various serial interfaces including CAN, timers and an in-circuit

debugging port. The PIC18 is used as a small and simple

interface between sensors and the CAN bus,

implementing a rudimentary ``intelligent sensor and actuator'' network.

Because of the extremely tight memory constraints and the simple

functionality of the firmware, we have written a custom C-language

interrupt-driven framework called ``PicCore''.

Unfortunately, there are few free software applications for PIC18

development. For example, there is no GCC cross-compiler for the PIC18

family. The GDB debugger does not support Microchip's ``ICD2'' in-circuit

debugging tool. Our current development environment consists of Microchip's

no-cost Windows-based integrated development

environment (MPLAB IDE) [pic], graciously donated copies of

HI-TECH Software's PICC-18 C compiler [C18], and Microchip's ICD2

debugger/programmer. Our failure to get MPLAB to run under emulators

such as WINE unfortunately require us to have Windows-based development

environments for the PIC18 developers. Developing our own PIC18

development tools would exceed the resources of our project, so for now

we have resigned ourselves to operate with two development environments.

We are currently searching for equivalent hardware that has better

free software development support.

6 Ground Systems

The software and hardware components on the ground (as shown in

Figure 1) have several objectives:

-

Maintain the safety of all participants and bystanders.

- Initiate the launch sequence (with means of emergency abort).

- Receive and record telemetry data from the vehicle during flight,

- Receive and record video broadcast from the vehicle during flight,

- Initiate manual recovery procedures if the flight software appears

to be failing.

Due to our small budget, our volunteer team has always relied on the

kindness of strangers for available computing hardware. As a result,

we need to be able to run our software on as many hardware and

software configurations as possible. We have chosen Java as our ground

systems language because Java byte-code enables us to run our code on

any sufficiently powerful platform. Java's automatic memory management

and simple GUI framework make ideal tools for user interfaces and

data visualization. Java is well known: many of the developers

in our group are familiar with it.

6.1 Launch Control Software

The launch control software is a Java application which steps through an

automated launch sequence. The sequence of events is coordinated with the

rocket and launch tower via ARRL 802.11b wireless links: the launch

tower may be several kilometers away from launch control for safety

reasons. Safety systems include manual interlocks and a

rocket-controlled interlock triggered on flight computer diagnostic

information. These interlocks prevent accidental launches

in the event of software or hardware

failure.

The launch tower computer is the same as the rocket's flight computer:

a PC104 stack with 5x86 processor, 802.11b card, power supply and

nonvolatile flash memory. The controller even has a CAN bus:

a CAN-based relay board controls launch tower hardware such

as strobe warning lights, sirens, and the rocket motor ignition relay.

6.2 Telemetry View Software

When the rocket is at its peak altitude of 23 km (70,000 ft), it is

almost impossible to visually ascertain what is

happening. The ``Rocketview'' telemetry

display software is used by flight personnel and

interested bystanders to observe the rocket's

status. The flight controller uses telemetry information to decide whether the

flight sequence is proceeding according to plan: if not, the

range safety officer can manually deploy the recovery system

using the emergency 2 m radio uplink.

The Rocketview application displays data received from the rocket via

ARRL 802.11b wireless link. The display includes 6 strip

charts (X, Y, and Z position as well as roll, pitch and yaw attitude),

several text fields, and a free-form console log for

miscellaneous messages from the flight computer.

The Rocketview application was modeled after a GTK-based C program

used for LV1. Because Rocketview is written in Java, it can take advantage

of Java's graphics capabilities and of such

open source components as the

JFreeChart charting tool [jfr].

6.3 Uplink Software

The uplink system is an emergency backup communication link.

The link is manually activated by the flight controller in case the flight computer

fails to deploy the recovery system. The uplink computer runs a Java

application which communicates via serial port with a

Yaesu 50 W 2 m amateur transceiver. Upon user command, the application

keys the Yaesu transmitter and generates a series of DTMF tones

(the familiar touch-tone telephone tones) which are received by the

recovery CAN node on the rocket. Besides emergency commands, the uplink

software can also generate a small number of CAN bus

commands for diagnosis purposes.

6.4 Video Capture System

Amateur TV signals received from the color camera on the rocket are

recorded on tape and displayed live on a monitor.

The flight personnel and bystanders

can thus observe the flight from the rocket's point of view.

The rocket uses a video overlay board to to display position and flight

computer status information. Because the ATV transmitter is higher power

and lower bandwidth

than the ARRL 802.11b transmitter, this display functions as a

backup telemetry downlink.

7 Collaboration Software

Before the LV2 project, PSU's Electrical and Computer

Engineering department hosted a web site and Majordomo list

server [maj] for PSAS activities. The site was primarily

used to promote recruitment and showcase progress. No centralized

version control was used and only one or two people updated the web

site. Nearly all engineering documentation was passed back and forth

between individuals using private email and removable computer media.

This collaboration model was ill-suited to the size and

complexity of the LV2 project: it was too difficult for team

members to share their efforts quickly and effectively.

To resolve these problems, PSU agreed to host a donated Pentium-class

computer. By co-locating a PSAS-owned computer, we gained flexibility

in service provisioning and the flexibility to set up and experiment

with collaboration software.

Four of the team members with significant system administration

experience have administrative privileges.

Anyone on the team can get OpenSSH [ssh] shell accounts for

purposes including software development and document preparation. PSU

creates a backup of this system nightly using Amanda [ama].

Mailman [mai], with its web interface, makes maintaining the

public announcement, team coordination, and site administration mailing

lists easy. In particular, mail list subscribers handle their own

subscription and mailing list preferences.

Although less than ideal, CVS [cvs] has made it

possible to share

and back up work on software and other development documents, even

across different operating systems.

The PSAS web site (http://psas.pdx.edu) still serves a

promotional purpose. However, it now also serves as an

ongoing project development notebook, with meeting minutes,

task lists, specifications, team work areas,

back-of-the-envelope calculations and diagrams online. This

is accomplished using TWiki [twi].

TWiki is a Perl CGI-based Wiki Wiki Web implementation by

Peter Thoeny and others,

comprising a web-based collaboration

platform designed for corporate and academic

intranets. Using TWiki, any team member can add or alter

site content using a web browser. TWiki automatically generates

hypertext links, allows for attaching multimedia content,

supports website search, can be configured to automatically

notify subscribers of changes and can remind users of

upcoming or overdue action items.

Begging for installation of tools from University staff, or working

through one or two authorized web secretaries using static HTML, would

severely constrain our entire project. Free software collaboration tools

make it possible for team members to contribute and collaborate at their

own pace, which dramatically improves our team's productivity.

8 PSAS Contributions

To date, amateur groups building custom avionics have developed private

software of little use to other groups. In contrast, the PSAS software

design is modular, based on inexpensive and open hardware, licensed

under the GNU General Public License, and available for download from

our web site. Any interested team is welcome to use and build on our work.

We strongly encourage other amateur groups to use our TWiki site,

mailing lists and CVS tools to collaborate with us on our projects:

advancing the state of the art through wider community collaboration.

A few of our free software and open hardware projects available

for use are:

-

Gerbertiler. A Perl script which tiles together printed circuit

board layout files. Tiling together many small boards into one large

board significantly reduces the one-time fee associated with having a

single board produced.

- Misc. CAN node. A 4 x 7 cm board for prototyping PIC18F458/CAN

node applications. Complete schematics, board layout files and working

code are available.

- PicCore. An interrupt-driven framework, peripheral APIs and network

drivers for the PIC18F4xx family of microcontrollers, written using

HI-TECH Software's PICC-18 C compiler.

- GPL-GPS. As discussed in Section 5.2,

GPL-GPS is a project to create free firmware for any Zarlink GP4020-based

GPS receiver board.

- LV1 IMU. A design for an inertial measurement unit

that costs less than $150 to build. Complete schematics, board layout

files and CAN node interface software are available.

- CAN Bus Driver. Modest changes to Arnaud Westenberg's Linux CAN

Bus Driver (Section 5.1.4) customize it to our

COTS flight computer board and are being contributed back to that

project. More importantly, we plan to create and contribute an RTLinux

CAN Bus Driver derived from that work.

- Navigation Algorithms. The signal processing algorithms for

approximating system location (Section 3.1) may be

adaptable to other combined inertial and GPS navigation applications.

9 Next Steps and Future Work

In late June or early July 2003, we are planning a low-altitude launch

to flight test the avionics system to 6 km (20,000 ft) in central Oregon.

This test will verify the basic operation of the critical hardware

and software systems during flight. Systems to be tested include:

-

Avionics. The flight computer software including crude navigation

algorithms, the ARRL 802.11b telemetry link, the emergency uplink

system, and critical sensors and actuators such as the IMU and recovery

system.

- Launch Tower. Launch tower computer, launch software, umbilical

cord and launch safety systems.

- Ground Computers. telemetry display and uplink software.

In September 2003, we are planning to build on the June results and

launch to 23 km (75,000 ft) in the Black Rock Desert of Nevada. By the

September launch, we hope to:

-

Migrate the flight computer software to RTLinux.

- Improve the sensor suite, including a next generation IMU, the first

generation of the GPL-GPS, and a magnetometer.

- Improve the navigation algorithms, including real-time GPS-aided

inertial navigation routines to calculate position, attitude and

trajectory.

- Upgrade the ARRL 802.11b telemetry link to use forward error

correction algorithms to improve the quality of data received and

provide an ability to confidently reconstruct some amount of lost

data.

- Integrate the GPL-GPS receivers into the rocket and base station,

creating a local differential GPS system.

After these two launches we will begin a parallel development effort to:

-

Develop a steerable hybrid motor system, probably using liquid injection

thrust vector control.

- Further tune the navigation algorithms in the avionics system through

simulations and experiments with ducted fans.

By late 2004 or early 2005 we hope to begin the integration of these two

systems and begin the first of many test flights with an active

guidance system in place. Instead of trying to fly a fully actively

guided rocket in one step, we plan to continue our careful,

incremental approach to development. For example, by increasing the

gain of the control system while removing fin area, we can build

confidence in the navigation system as the rocket becomes more and more

unstable because of the lack of fins.

By late 2005 or early 2006 we hope to have an actively guided, possibly

staged, rocket lifting research projects to high altitudes,

if not to the edge of space.

10 Conclusion

The PSAS software system employs integrated computing, from 8 bit and

32 bit microcontrollers through common PC laptop and server hardware.

The system hosts a wide variety of visualization, device control,

software development, promotional and coordination roles. Data flows

through real-time serial and parallel buses as well as wireless links,

requiring only straightforward programming based on network

abstractions. Required tasks range from hard real time signal processing

in a preemptive multitasking environment to coordinating a caravan

of two dozen people to the Nevada desert. Our budget for development

equipment is quite small, and our team of contributors vary widely in

skill level and available time.

With minor exceptions, free software has helped us tackle all of these

technological and logistical problems. Commercial systems

could not

have scaled so widely, cost so little, offered so many choices,

offered free support and training, and integrated these many domains

together so well. Our group could not have grown as quickly, or achieved

our current level of sophistication, without free software and open

hardware.

Availability

For complete technical details on our projects, including launch

videos, technology overviews, white papers, source code, schematics, and

board designs, please visit http://psas.pdx.edu/.

Acknowledgements

Throughout this paper, we have acknowledged the important debt

we owe to developers of free software and previous amateur aerospace

groups who have made our project possible. We are extremely grateful for

the invaluable encouragement and financial support from Portland State

University's Computer Science and Electrical and Computer Engineering

Departments. We would like to thank the IEEE, AT&T and the NASA/Oregon

Space Grant, all of which have provided significant

financial support;

also

the companies which have donated materials and software such as

HI-TECH Software, ANSOFT, and Microchip. Finally, we would like to thank

Usenix for supporting our efforts to bring free software to the amateur

aerospace community, and Keith Packard for providing excellent counsel

on our paper.

References

- [alt]

-

John Coker's Rocket Pages: Altimeter Comparison.

Web document. URL http://www.jcrocket.com/altimeters.shtml

accessed April 2, 2003 07:00 UTC.

- [ama]

-

Amanda, The Advanced Maryland Automatic Network Disk Archiver.

Web document. URL http://www.amanda.org/ accessed April 6,

2003 10:00 UTC.

- [arr]

-

Amateur Radio Relay League High-Speed Digital Networks.

Web document. URL http://www.arrl.org/hsmm/ accessed April 6,

2003 10:00 UTC.

- [C18]

-

HI-TECH Software PICC-18 Compiler.

Web document. URL http://www.htsoft.com accessed April 6,

2003 23:00 UTC.

- [can]

-

Robert Bosch GmbH CAN home page.

Web document. URL http://www.can.bosch.com/ accessed April 6,

2003 10:00 UTC.

- [CC99]

-

Charles K. Chui and Guanrong Chen.

Kalman Filtering.

Springer-Verlag, 1999.

- [csl]

-

United States Code, Title 49 Transportation, Chapters 701 and 703.

Web document. URL http://uscode.house.gov/title_49.htm accessed

April 7, 2003 06:19 UTC.

- [cvs]

-

CVS.

Web document. URL http://www.cvshome.org/ accessed April 6,

2003 09:30 UTC.

- [deb]

-

Debian.

Web document. URL http://www.debian.org/ accessed April 6,

2003 09:30 UTC.

- [FB99]

-

Jay A. Farrell and Matthew Barth.

The Global Positioning System and Inertial Navigation.

McGraw-Hill, 1999.

- [fsm]

-

FSMLabs - The RTLinux Company.

Web document. URL http://www.fsmlabs.com/ accessed April 6,

2003 10:00 UTC.

- [Gal95]

-

Bill O. Gallmeister.

POSIX.4: Programming for the real world.

O'Reilly and Associates, Inc., 1995.

- [gpsa]

-

GPL-GPS home page.

Web document. URL http://gps.psas.pdx.edu/ accessed April 6,

2003 23:00 UTC.

- [gpsb]

-

Zarlink Semiconductor GP4020 GPS Receiver Baseband Processor.

Web document. URL

http://products.zarlink.com/product_profiles/GP4020.htm accessed April

6, 2003 10:00 UTC.

- [ins]

-

Ariane 5 - Flight 501 Failure; Report by the Inquiry Board, European Space

Agency.

Web document. URL

http://www.ima.umn.edu/~arnold/disasters/ariane5rep.html accessed April

7, 2003 03:00 UTC.

- [jfr]

-

JFreeChart.

Freely available source code. URL

www.jfree.org/jfreechart/index.html accessed April 7, 2003 00:48 UTC.

- [kel]

-

OpenSource GPS Project.

Web document. URL http://home.earthlink.net/~cwkelley/ accessed

April 6, 2003 23:00 UTC.

- [Lab99]

-

Jean J. Labrosse.

MicroC/OS-II: The Real Time Kernel.

Miller Freeman, 1999.

- [lcb]

-

Linux CAN-bus Driver for the Intel(c) 82527 and Philips sja1000 controllers.

Web document. URL http://home.wanadoo.nl/arnaud/, accessed

April 7, 2003 07:21 UTC.

- [mai]

-

Mailman, the GNU Mailing List Manager.

Web document. URL http://www.list.org/ accessed April 6,

2003 09:30 UTC.

- [maj]

-

Majordomo.

Web document. URL http://www.greatcircle.com/majordomo/

accessed April 6, 2003 09:30 UTC.

- [mar]

-

MARS Amateur Rocketry Group.

Web document. URL http://www.mars.org.uk/ accessed April 6,

2003 23:00 UTC.

- [Mas03]

-

Anthony J. Massa.

Embedded Software Development with eCos.

Prentice Hall Professional Technical Reference, 2003.

- [pic]

-

Microchip, inc.

Web document. URL http://www.microchip.com/ accessed April 6,

2003 23:00 UTC.

- [rrs]

-

Reaction Research Society Space Shot.

Web document. URL

http://www.rrs.org/Projects/Launches/Space_Shot/space_shot.html

accessed April 2, 2003 07:00 UTC.

- [SB00]

-

George P. Sutton and Oscar Biblar.

Elements of Rocket Propulsion.

Wiley-Interscience, December 2000.

- [sls]

-

Spacelawstation.com: U.S. Space Law.

Web document. URL http://www.spacelawstation.com/uslaw.html

accessed April 7, 2003 06:20 UTC.

- [ssh]

-

OpenSSH.

Web document. URL http://www.openssh.org/ accessed April 6,

2003 09:30 UTC.

- [Tri]

-

Tripoli Rocketry Association.

Motor size classifications.

Web document. URL

http://www.tripoli.org/motors/motor_classes.html accessed April 3,

2003 19:00 UTC.

- [twi]

-

TWiki - A Web Based Collaboration Platform.

Web document. URL http://www.twiki.org/ accessed April 6,

2003 09:30 UTC.

- [un]

-

United Nations Office for Outer Space Affairs; International Space Law.

Web document. URL

http://www.oosa.unvienna.org/SpaceLaw/spacelaw.htm accessed April 7,

2003 02:00 UTC.

- [Wer92]

-

James R. Wertz, editor.

Space Mission Analysis and Design.

Microcosm, Inc., October 1992.

- [Win83]

-

Frank H. Winter.

Prelude to the Space Age: The Rocket Societies 1924-1940.

Smithsonian Institution Press, 1983.

This document was translated from LATEX by

HEVEA.

This paper was originally published in the

Proceedings of the

USENIX Annual Technical Conference (FREENIX Track),

June 9 – 14, 2003,

San Antonio, TX, USA

Last changed: 3 Jun 2003 aw

|

|

|